Accelerate Innovation with Verified, Sustainable Materials

Design faster. Build smarter. Stay compliant. CommonShare empowers R&D and product development teams to move from concept to prototype with verified, regulation-ready materials and components. With AI-curated sourcing intelligence and dynamic traceability, you can bring new products to market with speed and confidence.

The Challenge

Modern product innovation is bound by more than just creativity. R&D teams are now tasked with meeting regulatory thresholds (like REACH and ZDHC), sourcing low-carbon materials, and aligning with corporate sustainability goals without slowing down development cycles.

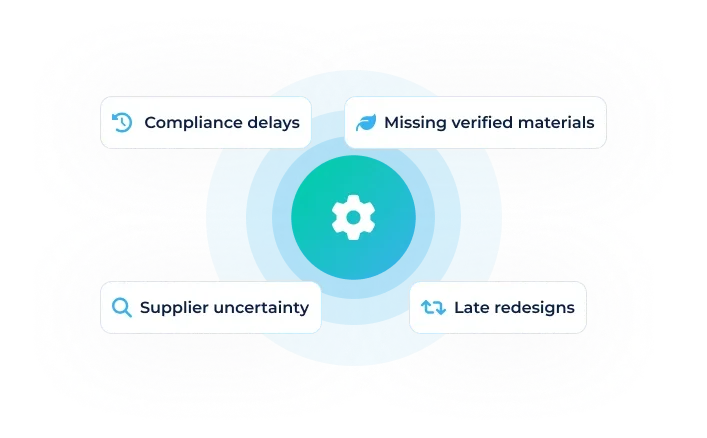

Common Pain Points

- Time-consuming compliance checks for new materials

- Uncertainty around supplier readiness or lead times

- Lack of access to verified, sustainable components

- Redesign loops due to spec changes or late-stage compliance issues

How CommonShare Helps

With CommonShare, your development process becomes traceable from the start powered by AI insights, verified supplier data, and a dynamic Bill of Materials that evolves with your goals.

Traceable Bill of Materials (BOM)

Design with confidence using a configurable BOM that surfaces REACH-compliant, lead-free, and low-carbon components backed by third-party data.

Verified Supplier & Material Screening

Instantly see which materials meet your performance and compliance requirements and which suppliers are already onboarded and trusted by your team.

Impact & Footprint Tracking

Make smarter design decisions with built-in visibility into carbon impact, sourcing region, and certification status.

Key Features

- AI-powered material filtering for REACH, ZDHC, and other standards

- Sustainability scorecards and carbon impact ranking

- Integrated supplier data from procurement and supply chain teams

- Dynamic updates as regulations and specs evolve

- Fast go/no-go decision support on new materials

Case Study: Building Low-Carbon Products, Faster

Industry: Consumer Goods / Apparel / Packaging Focus: Sustainable innovation, supplier validation, regulatory alignment

Keywords: low-carbon design, REACH compliance, traceable materials, sustainable product development

An R&D team at a leading consumer brand needed to launch a new product line under tight sustainability guidelines:

- All materials had to be REACH-compliant

- No paints or coatings could contain lead

- The final product needed to meet carbon footprint benchmarks

- Ideally, suppliers would be already onboarded to avoid delays

- 1Design with Verified Components Using CommonShare’s BOM tool, the team:

- Filtered materials for REACH and lead compliance

- Ranked polymers and textiles by carbon impact

- Avoided design rework by validating specs upfront

- "– Product Innovation Lead

Knowing a material is REACH-compliant before we spec it saves us from redesign loops later.

" - 2Leverage Existing Supplier Intelligence Instead of starting from scratch, the team tapped into supplier data from Procurement and Supply Chain:

- Reused three suppliers with proven performance

- Avoided delays and renegotiations

- Kept timelines on track for launch

- "– Senior R&D Manager

We used 3 existing suppliers who had the exact specs reducing our development time without compromising on standards.

" - 3Faster Vendor Decisions via the Ecosystem Directory Rather than onboard new suppliers, the team filtered existing partners using:

- Identify pre-verified suppliers with the needed material

- Check certifications, environmental impact, and sourcing region

- Make confident go/no-go decisions before finalizing the spec